Multiplex Gemini Build

I collected my Gemini from Galaxy Models on the way

home on a Monday

afternoon. It had it's maiden flight the following

Saturday. Here are a few pictures that I took during the

build. It's not a full "build log" because there wasn't really a

lot to do.

Even the packaging is quite

impressive. I took the time to unpack everything and check it off

against the parts list. Nothing was missing and it helps to know

what every thing is so that you don't start putting the wrong bits

together !

Even the packaging is quite

impressive. I took the time to unpack everything and check it off

against the parts list. Nothing was missing and it helps to know

what every thing is so that you don't start putting the wrong bits

together !

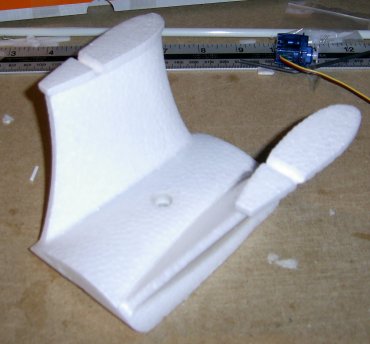

I had purchased four Hitec HS-55s to use in this model. They are

slightly larger than the MPX parts, so the mounting holes in the

fuzelarge needed to me extended backwards by a small amount. The

picture shows where I cut away the foam.

Once the control rods and snakes were

installed the servos were secured in place using hot glue. Using

the outermost hole on the servo arms means the rod lines up

correctly and the throws are about right.

Once the control rods and snakes were

installed the servos were secured in place using hot glue. Using

the outermost hole on the servo arms means the rod lines up

correctly and the throws are about right.

Here's a tip: Don't glue the snakes in too near the ends of the

slot in the fuzelarge as the need to move a little as the servo arm

turns. This is more important at the tail end of the

snakes. Also it reduces the risk of gluing the inner and outer

tubes together, or worse still gluing the rod into the snakes.

The manual was not very helpful

when it came to putting the tail wheel assembly together.

The part of the wire sticking up has to

be bent into shape such that it lies in the position of

its shadow in the picture. The manual says to

use "a pair of combination pliers" but I couldn't see how to do this

without putting stress on the plastic parts in the process.

The manual was not very helpful

when it came to putting the tail wheel assembly together.

The part of the wire sticking up has to

be bent into shape such that it lies in the position of

its shadow in the picture. The manual says to

use "a pair of combination pliers" but I couldn't see how to do this

without putting stress on the plastic parts in the process.

In the end I realised I could put it in

the vice the other way up, and use the 5-7mm of wire that is needed

below the bracket to cover the depth of the vice jaw while bending the

wire to shape.

In the end I realised I could put it in

the vice the other way up, and use the 5-7mm of wire that is needed

below the bracket to cover the depth of the vice jaw while bending the

wire to shape.

With the hinge and bracket glued in

place I cut a slot for the wire as described in the manual.

With the hinge and bracket glued in

place I cut a slot for the wire as described in the manual.

In the manual it says "glue the wire into

the rudder using plenty of cyano. Well I tried this, but since

cyano isn't a "space filling" glue it didn't seem very secure to me.

In the manual it says "glue the wire into

the rudder using plenty of cyano. Well I tried this, but since

cyano isn't a "space filling" glue it didn't seem very secure to me.

So I cut out a small piece from some

spare foam and glued it in place to fill the rest of the slot.

I've outlined the extra piece in the picture. The excess was

trimmed off after the glue had set.

So I cut out a small piece from some

spare foam and glued it in place to fill the rest of the slot.

I've outlined the extra piece in the picture. The excess was

trimmed off after the glue had set.

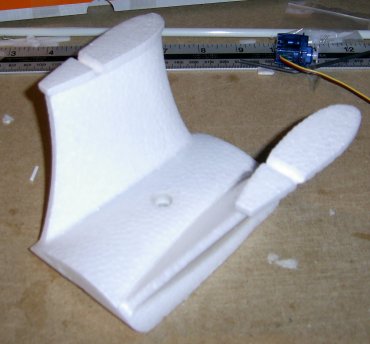

The cabane parts after gluing.

With any of the parts where there is a slot into which another part

fits, don't put glue on the sides as it will "grip" before you

get the parts fully together. Put plenty of glue in the bottom of

the slot so that as the parts come right together it will be forced up

the sides of the joint.

The cabane parts after gluing.

With any of the parts where there is a slot into which another part

fits, don't put glue on the sides as it will "grip" before you

get the parts fully together. Put plenty of glue in the bottom of

the slot so that as the parts come right together it will be forced up

the sides of the joint.

When installing the tail section it is also important to consider which

parts come into contact first and which parts need to slide over each

other before the final position is reached. If you put glue on

these parts it will grip before you get the parts fully together (I

know because this happened to me when putting the elevators into my

Twinstar II. I didn't make the same mistake this time).

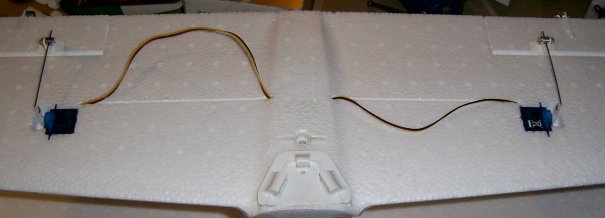

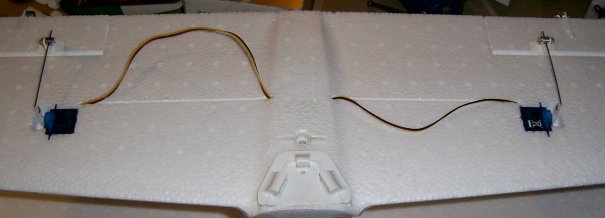

The wings, cabane and wing struts all glued together.

The aileron linkages are quite fiddly to get together. Unlike the

servo mounts in the fuzelarge sides, the aileron mounts did not require

any adjustments.

Here it is all put together for the first time.

The manual says to install the ESC

behind the motor "suspended on its cables", but I decided to

provide a firm mount to stop it moving about in flight. I cut a

small strip of balsa to size and glued it to the motor mounts in the

sides of the fuzelarge. The ESC is held in place on the mount

with velcro.

The manual says to install the ESC

behind the motor "suspended on its cables", but I decided to

provide a firm mount to stop it moving about in flight. I cut a

small strip of balsa to size and glued it to the motor mounts in the

sides of the fuzelarge. The ESC is held in place on the mount

with velcro.

The final thing to do was to add the transfers. The manual says

this should be done before the major parts are glued together, but I

was

impatient to get it built. The only parts that would be difficult

to do are the inner surfaces of the wings, so mine have remained

undecorated.

So, by the following Saturday it was all ready to go. The last

thing to do was to set up the servo throws and exponentials on my

transmitter. I set these all to the values in the manual.

With a Thunder Power Prolite TP-2100 pack fitted, and a ferrite ring on

the ESC lead, and the Futaba receiver fitted on the top of the

lower wing, the CofG came out 20mm behind the spar in the top

wing. The manual suggests 75mm back from the "nose" of the

top wing which would be on the spar, so mine is a little bit to the

rear of that point.

Post maiden flight

adjustments

The maiden flight was a little bit stressful because I

seemed to have

set the elevator linkage with the servo NOT in it's neutral

position. As a result it need all the nose down trim my

transmitter had and a bit more besides. But I got it round a

couple of circuits and managed a reasonable landing.

So post flight I reset the linkage and reset the transmitter

trim. On the second flight it became obvious that some down

thrust was needed on the motor mount. The design of the mount

makes this adjustment very easy. 1) Remove spinner and prop. 2)

loosen of the middle bolts on each side. 3) Turn top bolts on

each side in one turn and the bottom bolts out half a turn. 4)

Tighten the middle bolts and refit the prop and spinner.

The third flight was much better but it was still climbing when the

throttle was opened, so a further half turn in was added to the top

motor mount bolts.

By now I was confident enough to ask someone to use my camera to

get

some video

of the Gemini in action

.

Even the packaging is quite

impressive. I took the time to unpack everything and check it off

against the parts list. Nothing was missing and it helps to know

what every thing is so that you don't start putting the wrong bits

together !

Even the packaging is quite

impressive. I took the time to unpack everything and check it off

against the parts list. Nothing was missing and it helps to know

what every thing is so that you don't start putting the wrong bits

together !

Once the control rods and snakes were

installed the servos were secured in place using hot glue. Using

the outermost hole on the servo arms means the rod lines up

correctly and the throws are about right.

Once the control rods and snakes were

installed the servos were secured in place using hot glue. Using

the outermost hole on the servo arms means the rod lines up

correctly and the throws are about right. The manual was not very helpful

when it came to putting the tail wheel assembly together.

The part of the wire sticking up has to

be bent into shape such that it lies in the position of

its shadow in the picture. The manual says to

use "a pair of combination pliers" but I couldn't see how to do this

without putting stress on the plastic parts in the process.

The manual was not very helpful

when it came to putting the tail wheel assembly together.

The part of the wire sticking up has to

be bent into shape such that it lies in the position of

its shadow in the picture. The manual says to

use "a pair of combination pliers" but I couldn't see how to do this

without putting stress on the plastic parts in the process.  In the end I realised I could put it in

the vice the other way up, and use the 5-7mm of wire that is needed

below the bracket to cover the depth of the vice jaw while bending the

wire to shape.

In the end I realised I could put it in

the vice the other way up, and use the 5-7mm of wire that is needed

below the bracket to cover the depth of the vice jaw while bending the

wire to shape. With the hinge and bracket glued in

place I cut a slot for the wire as described in the manual.

With the hinge and bracket glued in

place I cut a slot for the wire as described in the manual. In the manual it says "glue the wire into

the rudder using plenty of cyano. Well I tried this, but since

cyano isn't a "space filling" glue it didn't seem very secure to me.

In the manual it says "glue the wire into

the rudder using plenty of cyano. Well I tried this, but since

cyano isn't a "space filling" glue it didn't seem very secure to me. So I cut out a small piece from some

spare foam and glued it in place to fill the rest of the slot.

I've outlined the extra piece in the picture. The excess was

trimmed off after the glue had set.

So I cut out a small piece from some

spare foam and glued it in place to fill the rest of the slot.

I've outlined the extra piece in the picture. The excess was

trimmed off after the glue had set. The cabane parts after gluing.

With any of the parts where there is a slot into which another part

fits, don't put glue on the sides as it will "grip" before you

get the parts fully together. Put plenty of glue in the bottom of

the slot so that as the parts come right together it will be forced up

the sides of the joint.

The cabane parts after gluing.

With any of the parts where there is a slot into which another part

fits, don't put glue on the sides as it will "grip" before you

get the parts fully together. Put plenty of glue in the bottom of

the slot so that as the parts come right together it will be forced up

the sides of the joint.

The manual says to install the ESC

behind the motor "suspended on its cables", but I decided to

provide a firm mount to stop it moving about in flight. I cut a

small strip of balsa to size and glued it to the motor mounts in the

sides of the fuzelarge. The ESC is held in place on the mount

with velcro.

The manual says to install the ESC

behind the motor "suspended on its cables", but I decided to

provide a firm mount to stop it moving about in flight. I cut a

small strip of balsa to size and glued it to the motor mounts in the

sides of the fuzelarge. The ESC is held in place on the mount

with velcro.