The LA-Heli Rotorshape

Sometime last year I was looking at the Robot Birds web site and I

came across their web page for the Rotorshape

from LA-heli. I just

had to have one!

This is the body of the

Rotorshape. It's just two tear-drop shaped sides, a platform for

the battery, a mount for the motor and undercarriage and a mount for

the two rotor control servos.

This is the body of the

Rotorshape. It's just two tear-drop shaped sides, a platform for

the battery, a mount for the motor and undercarriage and a mount for

the two rotor control servos.

The parts are glued together with CA,

but I decided to add some extra reinforcements in the form of some

balsa strips to increase the gluing area.

The parts are glued together with CA,

but I decided to add some extra reinforcements in the form of some

balsa strips to increase the gluing area.

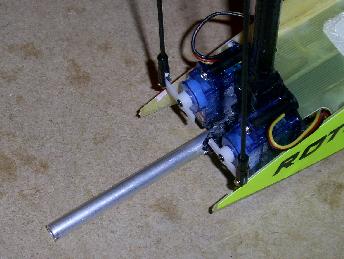

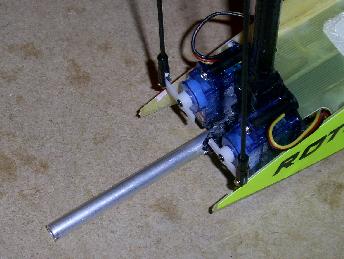

I didn't take many pictures during the

build, but here it is with the motor installed, the main boom and rotor

mast fitted (both carbon tubes) and the head assembled thought the

blades had not yet been covered.

I didn't take many pictures during the

build, but here it is with the motor installed, the main boom and rotor

mast fitted (both carbon tubes) and the head assembled thought the

blades had not yet been covered.

Imfact I didn't take any more

pictures until after it had flown a few times. The maiden

was carried out on a day when the wind was really a bit too strong, but

it flew well from it's first launch. The small wheels mean that

on a grass field the only practical way to get it flying is with a hand

launch.

Imfact I didn't take any more

pictures until after it had flown a few times. The maiden

was carried out on a day when the wind was really a bit too strong, but

it flew well from it's first launch. The small wheels mean that

on a grass field the only practical way to get it flying is with a hand

launch.

It took quite a few flights to get used to its flying

characteristics. Although you fly it like a conventional fixed

wing model (with alierons and elevator on the right stick), the way it

reacts to control inputs takes a while to learn. I can best

describe it as being "radio guided" rather than "radio

controlled". There is quite a delay between the control input and

the model reacting as it "wobbles around the sky". Since

there very little to actualy see in the sky it is very easy to get

disorientated and not know in which direction it is actually

pointing. Consequently I crashed it several times as a result of

it getting a bit to far away and then rolling it the wrong

way. Quite remarkably these crashes often resulted in no damage

at all, but once the rotor mast shapped and later the main boom snapped

as shown on the right.

The repair was quite simple. The

boom was snapped off and a short section of aluminium tube glued (with

epoxy) inside the carbon tube. The fit was quite close so I put

some epoxy into the ends of the carbon tube so that it would be spread

along the aluminium as it was inserted.

The repair was quite simple. The

boom was snapped off and a short section of aluminium tube glued (with

epoxy) inside the carbon tube. The fit was quite close so I put

some epoxy into the ends of the carbon tube so that it would be spread

along the aluminium as it was inserted.

I spread a thin film of epoxy onto the rod before

putting it together and the excess neatly joined the carbon tube ends.

I spread a thin film of epoxy onto the rod before

putting it together and the excess neatly joined the carbon tube ends.

After I had been flying the Rotorshape

for a few weeks, I decided to add a rudder to improve the

control. Although it flew well without a rudder, it is now much

easier to control in turns. The rudder was made from a

piece of "pizza base", the control horn was cut out of an old vending

machine card and epoxied into a slot cut in the rudder. The

hinge is nothing more than a strip of PVC tape. There

was space in the fuzelage just infront of the rotor mast to mount

a small 5g servo.

After I had been flying the Rotorshape

for a few weeks, I decided to add a rudder to improve the

control. Although it flew well without a rudder, it is now much

easier to control in turns. The rudder was made from a

piece of "pizza base", the control horn was cut out of an old vending

machine card and epoxied into a slot cut in the rudder. The

hinge is nothing more than a strip of PVC tape. There

was space in the fuzelage just infront of the rotor mast to mount

a small 5g servo.

The long contro rod had to be

repositioned as at first the rotor blades sometimes hit the rod at

ripped the horn out of the rudder.

The long contro rod had to be

repositioned as at first the rotor blades sometimes hit the rod at

ripped the horn out of the rudder.

The small wheels and narrow width

of the undercarriage mean that landings must be directly into wind

otherwise the model tends to topple over. The blades are held in

place with small sacrificial balsa pegs, which break when the blade

tips hit the ground and save the blades from damage. The small

wheels and lack of a steerable tail wheel also mean the land launching

is the only viable means of take off. Even in a slight

breeze the rotors can be spun up to almost flying speed by holdiing the

model nose up, then only a few paces at walking speed will be needed to

get the rotors up to full speed. Mine only needs half

throttle and a gentle "push into the air" to launch.

The small wheels and narrow width

of the undercarriage mean that landings must be directly into wind

otherwise the model tends to topple over. The blades are held in

place with small sacrificial balsa pegs, which break when the blade

tips hit the ground and save the blades from damage. The small

wheels and lack of a steerable tail wheel also mean the land launching

is the only viable means of take off. Even in a slight

breeze the rotors can be spun up to almost flying speed by holdiing the

model nose up, then only a few paces at walking speed will be needed to

get the rotors up to full speed. Mine only needs half

throttle and a gentle "push into the air" to launch.

Click

on this image to get to a video of my Rotorshape flying.

Click

on this image to get to a video of my Rotorshape flying.

Rudder Modifications

In the pictures above you can clearly see the rudder control rod above

the main boom. In this position is is rather vulnerable to rotor

strikes if the model tips over when landing. The shock to

the servo when this happens has so far stripped the gears on three

servos. I've also had to replace the rudder once and re-glue the

control horn twice.

So, I decided to alter things so that the rudder control rod now lies

underneath the main boom which will hopefully protect it from rotor

strikes.

The load on the servo is quite

small so I chose to simply attach the servo to the main boom with "hot

glue". Although this has moved the servo back further behind the

CofG it's still close ehough not to have made any noticable difference

to the trim.

The load on the servo is quite

small so I chose to simply attach the servo to the main boom with "hot

glue". Although this has moved the servo back further behind the

CofG it's still close ehough not to have made any noticable difference

to the trim.

The rudder control horn needed to be enlarged as it needs to clear the

back end of the main boom which is immediatley ahead of the front edge

of the rudder surface below the horizontal

stabiliser. As before the control surface was cut out from

a "pizza base", the control horn is a piece from an old magantic strip

payment card and it is held in the rudder with some epoxy. The

hinge is made from "blenderm" tape.

I've added a small skid to the

bottom of the boom to stop the bottom of the rudder touching the

ground. Looking at the picture I think I still need to trim off

the bottom edge of the rudder a bit more.

I've added a small skid to the

bottom of the boom to stop the bottom of the rudder touching the

ground. Looking at the picture I think I still need to trim off

the bottom edge of the rudder a bit more.

Bigger Wheels

One evening in very calm winds I tried a "touch and go" for the first

time. It wasn't really planned it just happened. After a

landing the rotor was still spinning and I just opened up the throttle

again and off it went :) Next time round I kept it moving on the

ground, opened it up and off it went again :) So, having

mastered touch and goes, a few days later I decided to try a

take-off from a standing start. The wind was about 10mph and with

it sitting on the ground with

the rotor tilted all the way back it was spinning up quite fast so I

was sure I could get it to fly off the ground. The biggest problem was

that to start with the small wheels were getting stuck in the uneven

grass, but once the

rotor started to produce some lift it could start to move forward

without

nosing over. With the rudder I was able to keep it

pointing directly into the breeze, and once moving forward the rotor

quickly spun up to flying speed and it lifted off smoothly without

rolling either way. The cure to the problem caused by the small

wheels was obvious... fit some bigger wheels !

On my way home from work yesterday I had dropped into my LHS to get

some glues and as I looked at the racks of "stuff" I spotted some foam

wheels that looked about the right size....

Here you can see the old and new wheels for comparison. The old

ones were 35mm dia. and the new ones are 50mm dia. I used acouple

of short pieces of carbon rod to make up adapters to match the

wire diameter to the (larger) hole in the wheels.

If you look very closely you can see the tail boom has aquired an outer

sleeve over the spot where I snapped it a few weeks ago !

With the original wheels and an 8" prop

there was very little ground clearance. You can see the tip of

the prop has a green stain from all the grass it has been cutting while

going touch and goes !

With the original wheels and an 8" prop

there was very little ground clearance. You can see the tip of

the prop has a green stain from all the grass it has been cutting while

going touch and goes !

The bigger wheels have several advantages:

They run much better on a grass surface and don't get stuck between the

grass.

The prop ground clearance is increased to the point were the prop

doesn't strike the ground when the tail lifts during a take-off run.

The model sits more "nose up" on the ground which makes it easier to

spin up the rotor in a breeze and makes a take-off run shorter.

Click the picture below for a video.

The improvements were immediatley obvious when I first opened the

throttle with the model sitting on the grass. Without hesitation

it started to move forward and I found it could easily be steered with

the rudder (even without a steerable tail wheel). At first

there wasn't enough breeze to spin up the rotor but I patiently

waited for a thermal to come through. A quick spin with my

"digital pre-rotator" (*), and with the elevator stick all

the way back, it set off across the grass. It was surprised how

quickly the rotor spun up to flying speed but I managed to release the

elevator stick soon enough to prevent a premature lift-off. It

rose slowly into the air at which point a bit more throttle put it into

a steady climb :)

(*) My Finger !

Throttle to Aileron mix

When I tried a "dead stick" landing the other week I found the model

rolled quite sharply to the right when I closed the throttle. I

carefully noted how much left stick I needed (about 40%) to keep it

straight and how much throttle it needed to fly straight and level

(50%). I then set up two of the programmable mixes on

my Futaba FF7 to mix some throttle into the aileron.

I set the mix's "offset" to 50%, so at cruise throttle the

mix would make no difference to the ailerons. I had to guess on

the percentages for the mix but set them at 20% as a first guess.

The first thing I tried in flight was to switch on the mix when flying

straight and level to check that the offst point was correct. As

I hoped this made no difference to the trim.

Next I tried slowly reducing the throttle to check the mix percentage

was correct. However 20% was too much as the model now rolled

slightly to the left. After a couple of adjustments I've

settled on 15%. Now I can perform "dead stick" landings

without problems.

This is the body of the

Rotorshape. It's just two tear-drop shaped sides, a platform for

the battery, a mount for the motor and undercarriage and a mount for

the two rotor control servos.

This is the body of the

Rotorshape. It's just two tear-drop shaped sides, a platform for

the battery, a mount for the motor and undercarriage and a mount for

the two rotor control servos. The parts are glued together with CA,

but I decided to add some extra reinforcements in the form of some

balsa strips to increase the gluing area.

The parts are glued together with CA,

but I decided to add some extra reinforcements in the form of some

balsa strips to increase the gluing area.  I didn't take many pictures during the

build, but here it is with the motor installed, the main boom and rotor

mast fitted (both carbon tubes) and the head assembled thought the

blades had not yet been covered.

I didn't take many pictures during the

build, but here it is with the motor installed, the main boom and rotor

mast fitted (both carbon tubes) and the head assembled thought the

blades had not yet been covered.  Imfact I didn't take any more

pictures until after it had flown a few times. The maiden

was carried out on a day when the wind was really a bit too strong, but

it flew well from it's first launch. The small wheels mean that

on a grass field the only practical way to get it flying is with a hand

launch.

Imfact I didn't take any more

pictures until after it had flown a few times. The maiden

was carried out on a day when the wind was really a bit too strong, but

it flew well from it's first launch. The small wheels mean that

on a grass field the only practical way to get it flying is with a hand

launch. The repair was quite simple. The

boom was snapped off and a short section of aluminium tube glued (with

epoxy) inside the carbon tube. The fit was quite close so I put

some epoxy into the ends of the carbon tube so that it would be spread

along the aluminium as it was inserted.

The repair was quite simple. The

boom was snapped off and a short section of aluminium tube glued (with

epoxy) inside the carbon tube. The fit was quite close so I put

some epoxy into the ends of the carbon tube so that it would be spread

along the aluminium as it was inserted. I spread a thin film of epoxy onto the rod before

putting it together and the excess neatly joined the carbon tube ends.

I spread a thin film of epoxy onto the rod before

putting it together and the excess neatly joined the carbon tube ends. After I had been flying the Rotorshape

for a few weeks, I decided to add a rudder to improve the

control. Although it flew well without a rudder, it is now much

easier to control in turns. The rudder was made from a

piece of "pizza base", the control horn was cut out of an old vending

machine card and epoxied into a slot cut in the rudder. The

hinge is nothing more than a strip of PVC tape. There

was space in the fuzelage just infront of the rotor mast to mount

a small 5g servo.

After I had been flying the Rotorshape

for a few weeks, I decided to add a rudder to improve the

control. Although it flew well without a rudder, it is now much

easier to control in turns. The rudder was made from a

piece of "pizza base", the control horn was cut out of an old vending

machine card and epoxied into a slot cut in the rudder. The

hinge is nothing more than a strip of PVC tape. There

was space in the fuzelage just infront of the rotor mast to mount

a small 5g servo. The long contro rod had to be

repositioned as at first the rotor blades sometimes hit the rod at

ripped the horn out of the rudder.

The long contro rod had to be

repositioned as at first the rotor blades sometimes hit the rod at

ripped the horn out of the rudder.  The small wheels and narrow width

of the undercarriage mean that landings must be directly into wind

otherwise the model tends to topple over. The blades are held in

place with small sacrificial balsa pegs, which break when the blade

tips hit the ground and save the blades from damage. The small

wheels and lack of a steerable tail wheel also mean the land launching

is the only viable means of take off. Even in a slight

breeze the rotors can be spun up to almost flying speed by holdiing the

model nose up, then only a few paces at walking speed will be needed to

get the rotors up to full speed. Mine only needs half

throttle and a gentle "push into the air" to launch.

The small wheels and narrow width

of the undercarriage mean that landings must be directly into wind

otherwise the model tends to topple over. The blades are held in

place with small sacrificial balsa pegs, which break when the blade

tips hit the ground and save the blades from damage. The small

wheels and lack of a steerable tail wheel also mean the land launching

is the only viable means of take off. Even in a slight

breeze the rotors can be spun up to almost flying speed by holdiing the

model nose up, then only a few paces at walking speed will be needed to

get the rotors up to full speed. Mine only needs half

throttle and a gentle "push into the air" to launch.

Click

on this image to get to a video of my Rotorshape flying.

Click

on this image to get to a video of my Rotorshape flying.

The load on the servo is quite

small so I chose to simply attach the servo to the main boom with "hot

glue". Although this has moved the servo back further behind the

CofG it's still close ehough not to have made any noticable difference

to the trim.

The load on the servo is quite

small so I chose to simply attach the servo to the main boom with "hot

glue". Although this has moved the servo back further behind the

CofG it's still close ehough not to have made any noticable difference

to the trim.

I've added a small skid to the

bottom of the boom to stop the bottom of the rudder touching the

ground. Looking at the picture I think I still need to trim off

the bottom edge of the rudder a bit more.

I've added a small skid to the

bottom of the boom to stop the bottom of the rudder touching the

ground. Looking at the picture I think I still need to trim off

the bottom edge of the rudder a bit more.

With the original wheels and an 8" prop

there was very little ground clearance. You can see the tip of

the prop has a green stain from all the grass it has been cutting while

going touch and goes !

With the original wheels and an 8" prop

there was very little ground clearance. You can see the tip of

the prop has a green stain from all the grass it has been cutting while

going touch and goes !